Ball Valves

Home » Our Products » Manual Valves » Ball Valve

OUR PRODUCTS RANGE

Trusted Ball Valves Manufacturer

and Supplier

The team responsible for manufacturing Ball valves at Multitech Valves & Automation (MVA) has created a groundbreaking and long-lasting design that guarantees outstanding performance and a prolonged lifespan. As a renowned manufacturer and supplier of Ball valves in India, we strictly adhere to rigorous quality standards and possess international certification. MVA's Ball valve is widely recognized as a premier option because of its capability to endure high-pressure and temperature environments. Additionally, our valves can be operated through different means including electric, pneumatic, or alternative forms of actuation.

8 + Years of

working experience

India's Most Trustworthy Brand Name in Mfg. Premium Range in Manual Valves

Ball Valves :

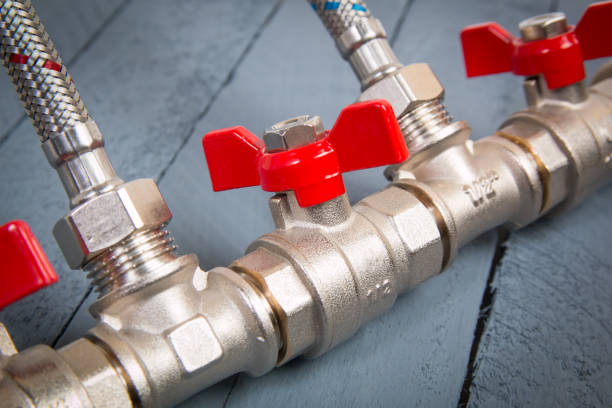

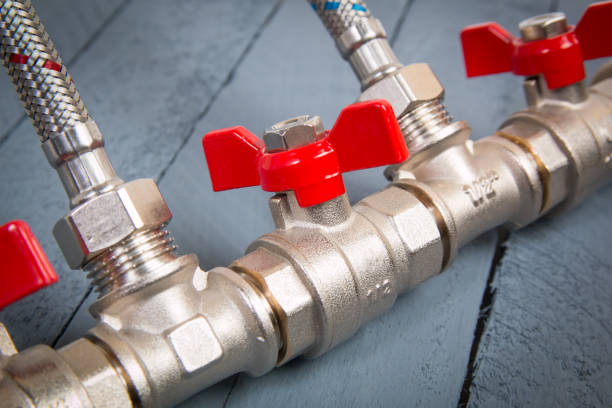

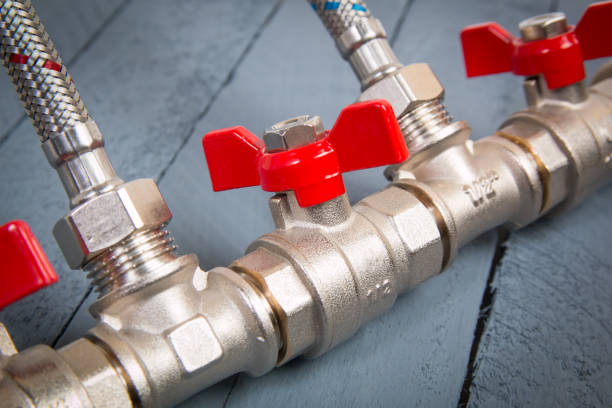

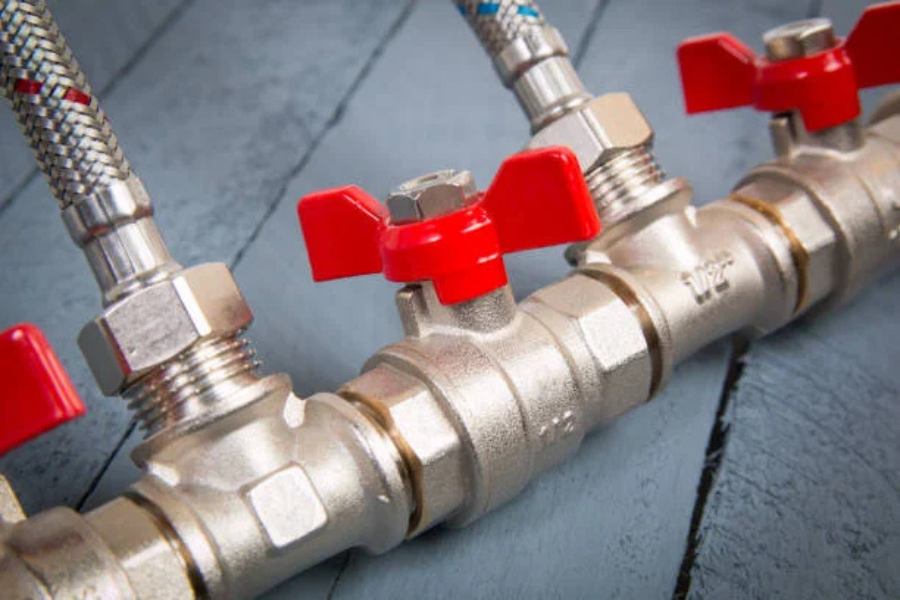

Ball valves are commonly used in industrial applications, plumbing systems, and various other fluid control systems due to their reliability, ease of operation, and ability to provide tight shut-off when closed. They are available in various materials such as brass, stainless steel, and PVC, and can handle a wide range of temperatures and pressures.

A ball valve is a type of valve used to control the flow of fluid through a pipe or tubing. It consists of a hollow, perforated, and pivoting ball with a hole (port) that aligns with the flow path when open and blocks the flow when closed. The ball is rotated 90 degrees by a handle or lever to control the flow.

Types of Ball Valves :

Applications :

- Fire protection

- Oil and Gas Industry

- Power Generation

- HVAC systems

- Petrochemical Industry

- Utilities

- Industrial processes

- Agriculture

- Marine and Shipbuilding

- Food and Beverage Industry

Features :

- Quarter-turn operation

- Low torque operation

- Minimal pressure drop

- Versatility

- Durability

Technical Details :

| MOC (Body/Side Piece) | Cast Steel (WCB), Stainless Steel (CF8, CF8M, CF3,CF3M) |

| Ball | CF8, CF8M,CF3M |

| Mfg. Std. | BS 5351 |

| Insp & Testing Std | BS 6755 / BS EN 12266-1 Design: Single Piece, Two Piece, Three Piece |

| Operation | Lever Optd. / Gear Optd. |

| End Connection | Screwed / Socket/ Flanged End |

| Size | 1½" to 14" (15 mm to 350 mm) |

| Class | 150#/300#/600#/900# |

inquire here

DOWNLOAD BROCHURE OF COMPANY

Our product range

inquire here

DOWNLOAD BROCHURE OF COMPANY

Ball Valves :

Ball valves are commonly used in industrial applications, plumbing systems, and various other fluid control systems due to their reliability, ease of operation, and ability to provide tight shut-off when closed. They are available in various materials such as brass, stainless steel, and PVC, and can handle a wide range of temperatures and pressures.

A ball valve is a type of valve used to control the flow of fluid through a pipe or tubing. It consists of a hollow, perforated, and pivoting ball with a hole (port) that aligns with the flow path when open and blocks the flow when closed. The ball is rotated 90 degrees by a handle or lever to control the flow.

Types of Ball Valves :

Applications :

Features :

- Fire protection

- Oil and Gas Industry

- Power Generation

- HVAC systems

- Petrochemical Industry

- Utilities

- Industrial processes

- Agriculture

- Marine and Shipbuilding

- Food and Beverage Industry

- Quarter-turn operation

- Low torque operation

- Minimal pressure drop

- Versatility

- Durability

- Fire protection

- Oil and Gas Industry

- Power Generation

- HVAC systems

- Petrochemical Industry

- Utilities

- Industrial processes

- Agriculture

- Marine and Shipbuilding

- Food and Beverage Industry

Features :

- Quarter-turn operation

- Low torque operation

- Minimal pressure drop

- Versatility

- Durability

Technical Details :

| MOC (Body/Side Piece) | Cast Steel (WCB), Stainless Steel (CF8, CF8M, CF3,CF3M) |

| Ball | CF8, CF8M,CF3M |

| Mfg. Std. | BS 5351 |

| Insp & Testing Std | BS 6755 / BS EN 12266-1 Design: Single Piece, Two Piece, Three Piece |

| Operation | Lever Optd. / Gear Optd. |

| End Connection | Screwed / Socket/ Flanged End |

| Size | 1½" to 14" (15 mm to 350 mm) |

| Class | 150#/300#/600#/900# |

inquire here

DOWNLOAD BROCHURE OF COMPANY

Ball Valves :

Ball valves are commonly used in industrial applications, plumbing systems, and various other fluid control systems due to their reliability, ease of operation, and ability to provide tight shut-off when closed. They are available in various materials such as brass, stainless steel, and PVC, and can handle a wide range of temperatures and pressures.

A ball valve is a type of valve used to control the flow of fluid through a pipe or tubing. It consists of a hollow, perforated, and pivoting ball with a hole (port) that aligns with the flow path when open and blocks the flow when closed. The ball is rotated 90 degrees by a handle or lever to control the flow.

Types of Ball Valves :

Applications :

Features :

- Fire protection

- Oil and Gas Industry

- Power Generation

- HVAC systems

- Petrochemical Industry

- Utilities

- Industrial processes

- Agriculture

- Marine and Shipbuilding

- Food and Beverage Industry

- Quarter-turn operation

- Low torque operation

- Minimal pressure drop

- Versatility

- Durability

Technical Details :

| MOC (Body/Side Piece) | Cast Steel (WCB), Stainless Steel (CF8, CF8M, CF3,CF3M) |

| Ball | CF8, CF8M,CF3M |

| Mfg. Std. | BS 5351 |

| Insp & Testing Std | BS 6755 / BS EN 12266-1 Design: Single Piece, Two Piece, Three Piece |

| Operation | Lever Optd. / Gear Optd. |

| End Connection | Screwed / Socket/ Flanged End |

| Size | 1½" to 14" (15 mm to 350 mm) |

| Class | 150#/300#/600#/900# |

Gate Valves :

A gate valve is a type of valve that controls the flow of fluid by moving a gate or wedge-shaped disc up and down within the valve body. This movement of the gate either allows or restricts the flow of the fluid through the valve. Gate valves are commonly used to start or stop the flow of liquids in pipelines.

A gate valve is generally used to completely shut off fluid flow or, in the fully open position, provide full flow in a pipeline. Thus it is used either in the fully closed or fully open positions. A gate valve consists of a valve body, seat and disc, a spindle, gland, and a wheel for operating the valve.

Types of Gate Valves :

Applications :

Features :

- Water and Wastewater Treatment

- Oil and Gas Industry

- Power Generation

- Chemical Processing

- Petrochemical Industry

- Pharmaceutical Industry

- Textile Industry

- Agriculture

- Marine and Shipbuilding

- Food and Beverage Industry

- Bi-Directional Flow

- Excellent Shut-Off Capability

- Quick Operation

- Straightforward Design

- Durable Construction

Technical Details :

| MOC | Cast Steel (WCB), Stainless Steel (CF8, CF8M, CF3,CF3M) Alloy Steel, Cast Iron (FG 260) |

| Mfg. Std | API 600 / BS 1414 |

| Insp & Testing Std | API 598 |

| Operation | Wheel Optd. / Gear Optd. / Electrical Actuator Optd |

| Material of Construction | Stainless Steel, Carbon Steel, Cast Iron, etc. |

| End Connection | Flanged End / Buttweld End |

| Size | 1½" to 24" (15 mm to 600 mm) |

| Class | 150#/300#/600#/900# |

Ball Valves :

Ball valves are commonly used in industrial applications, plumbing systems, and various other fluid control systems due to their reliability, ease of operation, and ability to provide tight shut-off when closed. They are available in various materials such as brass, stainless steel, and PVC, and can handle a wide range of temperatures and pressures.

A ball valve is a type of valve used to control the flow of fluid through a pipe or tubing. It consists of a hollow, perforated, and pivoting ball with a hole (port) that aligns with the flow path when open and blocks the flow when closed. The ball is rotated 90 degrees by a handle or lever to control the flow.

Types of Ball Valves :

Applications :

Features :

- Fire protection

- Oil and Gas Industry

- Power Generation

- HVAC systems

- Petrochemical Industry

- Utilities

- Industrial processes

- Agriculture

- Marine and Shipbuilding

- Food and Beverage Industry

- Quarter-turn operation

- Low torque operation

- Minimal pressure drop

- Versatility

- Durability

Technical Details :

| MOC (Body/Side Piece) | Cast Steel (WCB), Stainless Steel (CF8, CF8M, CF3,CF3M) |

| Ball | CF8, CF8M,CF3M |

| Mfg. Std. | BS 5351 |

| Insp & Testing Std | BS 6755 / BS EN 12266-1 Design: Single Piece, Two Piece, Three Piece |

| Operation | Lever Optd. / Gear Optd. |

| End Connection | Screwed / Socket/ Flanged End |

| Size | 1½" to 14" (15 mm to 350 mm) |

| Class | 150#/300#/600#/900# |

Globe Valves :

A globe valve is a type of valve used to regulate or stop the flow of fluid through a pipeline. It consists of a movable disk (or plug) that seats against a stationary ring (or seat) to control the flow. The disk is connected to a stem, which is operated by a handwheel or actuator to move it up or down, thereby opening or closing the valve.

Globe valves are characterized by their spherical body shape, hence the name "globe" valve. They are commonly used in applications where throttling or fine control of flow is required, as well as in systems where frequent operation is necessary. Globe valves can be designed with various configurations, such as straight, angle, or Y-pattern, to suit different installation requirements and flow conditions. They are widely used in industries such as oil and gas, power generation, and water treatment.

Types of Globe Valves :

Applications :

Features :

- Boiler feedwater systems

- Oil and Gas Industry

- Power Generation

- Chemical Processing

- Petrochemical Industry

- Steam systems

- Textile Industry

- Agriculture

- Marine and Shipbuilding

- Food and Beverage Industry

- Precise flow control

- Linear flow characteristics

- Easy maintenance

- Excellent shut-off capability

- Excellent shut-off capability

Technical Details :

| MOC | Cast Steel (WCB), Stainless Steel (CF8, CF8M, CF3,CF3M) Alloy Steel, Cast Iron (FG 260) |

| Mfg. Std. | BS 1873 |

| Insp & Testing Std | BS 6755 |

| Operation | Wheel Optd. / Gear Optd. / Electrical Actuator Optd. |

| End Connection | Flanged End / Buttweld End |

| Seat and Disk Material | Stainless Steel, Stellite, Teflon, etc. |

| Size | 1½" to 24" (15 mm to 600 mm) |

| Class | 150#/300#/600#/900# |

Butterfly Valves :

Butterfly valves are a family of quarter-turn rotational motion valves that are used in pipelines to shut-off flow. It is often said that butterfly valves can be used to regulate the flow. However, we do not recommend doing this, as it can damage the valve disk and have a negative effect on the sealing properties.

Butterfly valves are a family of quarter-turn rotational motion valves that are used in pipelines to shut-off flow. It is often said that butterfly valves can be used to regulate the flow. However, we do not recommend doing this, as it can damage the valve disk and have a negative effect on the sealing properties.

Types of Butterfly Valves :

Applications :

Features :

- Water and Wastewater Treatment

- Oil and Gas Industry

- Power Generation

- Chemical Processing

- Petrochemical Industry

- Pharmaceutical Industry

- Textile Industry

- Agriculture

- Marine and Shipbuilding

- Food and Beverage Industry

- Bi-Directional Flow

- Quarter-turn operation

- Low pressure drop

- Straightforward Design

- Minimal maintenance

Technical Details :

| BODY | CI (FG260) / CAST STEEL (WCB) Stainless Steel (CF8, CF8M, CF3,CF3M) |

| DISC | S.G.Iron / S.S (CF8, CF8M, CF3, CF3M) |

| Mfg. Std | BS 5155 / API 609 Insp & Testing Std : API 598 |

| Operation | Lever Optd. / Gear Optd. / End Connection: Wafer Type to Suit Flanges as per 150#, Table D, E & F / Double Flanged Type |

| Size | 11½" to 24" (40 mm to 600 mm) |

| Lining | Nitrile / EPDM/PTFE/VITON |

| Rating | PN10, PN16 |

check Valves :

Check valves are one-way or nonreturn valves that open with fluid movement and pressure, and close to prevent backflow of the pressure to upstream equipment such as pumps and compressors. In fact, check valves allow the fluid to flow in only one direction.

Check valves, also known as non-return valves or one-way valves, serve a crucial function in fluid systems by allowing flow in one direction while preventing backflow in the opposite direction.Check valves are generally installed in pipelines to prevent backflow. A check valve is basically a one-way valve, in which the flow can run freely one way, but if the flow turns, the valve will close to protect the piping, other valves, pumps etc.

Types of check Valves :

Applications :

Features :

- Water and Wastewater Treatment

- Oil and Gas Industry

- Power Generation

- Chemical Processing

- Petrochemical Industry

- Pharmaceutical Industry

- Textile Industry

- Agriculture

- Marine and Shipbuilding

- Food and Beverage Industry

- Bi-Directional Flow

- Excellent Shut-Off Capability

- Quick Operation

- Straightforward Design

- Durable Construction

Technical Details :

| MOC | Cast Steel (WCB), Stainless Steel (CF8, CF8M, CF3,CF3M) Alloy Steel, Cast Iron (FG 260) |

| Mfg. Std. | BS 1868 |

| Insp & Testing Std | BS 6755 |

| End Connection | Flanged End / Buttweld End |

| Size | 1½" to 24" (15 mm to 600 mm) |

| Class | 150#/300#/600#/900# |

Knife Edge Gate Valve :

A Knife Edge Gate Valve is specially designed for handling slurry, powder, pulp, viscous media, and abrasive fluids. Its sharp, bevelled gate cuts through thick and dense materials with ease, preventing clogging and ensuring smooth, reliable operation. Constructed with a rugged, compact body, this valve provides tight sealing, low-pressure drop, and long-lasting performance, even in harsh industrial conditions.

Ideal for industries such as mining, wastewater treatment, chemical processing, paper & pulp, cement, and food processing, the knife edge gate valve offers dependable flow isolation, easy maintenance, and efficient control of challenging media. It is the preferred solution wherever clean shutoff and durability are essential.

Types of Knife Edge Gate Valve :

Applications :

Features :

- Mining & Mineral Processing

- Wastewater Treatment Plants

- Pulp & Paper Industry

- Chemical & Process Industries

- Food & Beverage Processing

- Cement & Bulk Material Handling

- Power Plants

- Steel & Metal Industries

- Pharma & Biotech (Special Designs)

- Marine & Dredging

- Sharp Knife-Edge Gate

- Full Bore, Unrestricted Flow

- Robust, Compact Construction

- Tight Sealing Performance

- Corrosion-Resistant Materials

Technical Details :

| Material | Stainless Steel, wdb, ci |

| Size | 50MM TO 1000MM |

| Usage/Application | Industrial |

| Connection Type | LUG END |

| Pressure | 7 KG |

| I Deal In | New Only |

| Country of Origin | Made in India |

| Availability | In Stock |